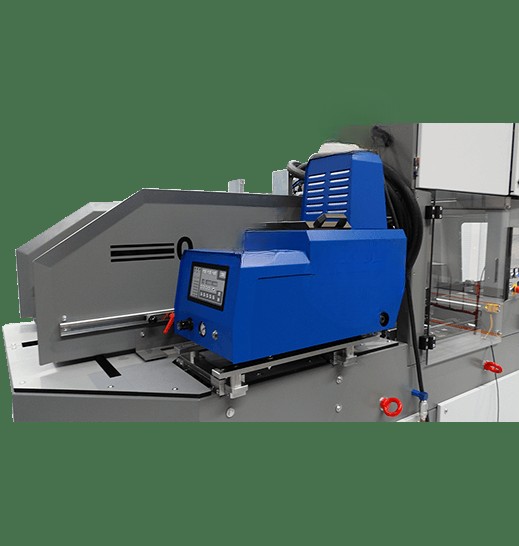

Box MACHINE

The Q is the newest innovation for all customers who ask for a flexible, robust and functional machine. It has been developed with the use of kits that allow to easily change the type of box to assemble.

Q has 6 speeds, which added the possibility of working with average speeds to adapt to meet your real production needs; it is designed to produce from 400 t.p.h. up to 1800 t.p.h.

In keeping with the rest of the Q “Quality” range there is a high level of compatibility between models with toolings and the forming sections being interchangeable, which is both a functional advantage as an economic savings.

MAIN FEATURES:

Machine evolved from the original Q machine.

PROGRAMMING THROUGH simple and user friendly TOUCH SCREEN.

Production increased in a 20% from the former versions, assembling up to 1800 T.P.H.

Can be linked to remote access kit .

Better access (tank located on the side, extraction of the compressor…)

OPERATION: Mechanical, Electrical and Pneumatical

GLUE SYSTEM: Hot Melt, Glue Injection

BOX DESIGN: Plaform®, P-84®, Citrus Box, C-1, Big Ear, Open column

PRODUCTION: From 400 up to 1800 TpH

TOTAL POWER: 6,6 Kw (W/O compressor)

NET WEIGHT: 1,500 Kg

ELECTRICAL SUPPLY: 380/220 V (3F+N+PE) – 50/60 Hz

CHANGE OF SIZE: By clamps with threaded rods and counters

CHANGE OF SIZE (IN TIME): 10 to 15 min. Aprox.

CHANGE OF DESIGN (IN TIME): 20 to 40 min. Aprox.

WORKING AIR PRESSURE: 7 BAR (7 kg/cm2)

AIR CONSUMPTION: 400 litres/minute (erecting Plaform® boxes on 1800 tph)

MACHINE FRAME: 4mm Steel plate

MACHINE DIMENSIONS: L:3425 mm.; A:1840 mm.; H:2175 mm